Processing is a typical interaction in many assembling organizations. Many organizations utilize various machines for this interaction. CNC machines are the most regularly utilized in processing. As mechanical technology assembling and use have changed, processing robots are presently a typical element in many assembling organizations.

Producers are partaking in the advantages that accompany the selection of processing robots in their tasks. Like other assembling activities that have been computerized with robots, you can do likewise for your processing tasks.

Here is a portion of the advantages you are probably going to appreciate by securing a processing robot for your tasks.

Undeniable Levels Of Flexibility

At the point when you utilize a processing robot, you can hope to appreciate undeniable degrees of adaptability from the robot. The processing robot arm can without much of a stretch turn at various points because of its six arms. This assists you with conveying items in various shapes without any problem.

With this benefit, a maker can expand the number of items they have in their portfolio quickly and economically. This converts into a more alluring monetary situation for the organization as deals increment combined with lower creation costs.

A robot additionally gives heaps of adaptability on the kind of machining instruments you can use with your robot. The robot can without much of a stretch handle a wide range of materials you use in processing. It can work with molds produced using mud, plant fiberglass, and even froth as effectively as it can process marble. Robots can undoubtedly direct their force to work even with the gentlest of materials without breaking them.

Lower Costs

The utilization of robots in your processing plant cuts down your creation costs essentially. To start with, the expense of gaining a robot is a lot slower than the expense of getting a conventional processing machine. With a lower cost of hardware procurement, the manufacturing plant can run beneficially.

Further, the expense of creation in the processing plant is CNC robots likewise altogether lower. Robots work quicker and are more exact than the typical processing machine. Further, with the expanded creation adaptability from the robot, you can deliver more at a lower cost in your production line.

Likewise, robots can deal with further developed undertakings without anyone else. This implies that you need fewer individuals to deal with a solitary assignment. Further decreasing the expense of creation.

When the robots are through with processing exercises in the plant, they can be reassigned to different errands. This implies that you don’t need to purchase a processing robot and another robot for different undertakings. This aids little assembling substances to save money on gear procurement costs.

With fewer breakdowns, you needn’t bother with the normal assistance and support on your robot. You would thus be able to keep your creation cycle running consistently. Expanding your creation levels and main concern without any problem.

Robots Are Easy To Program

Another benefit that you will acquire from getting a processing robot is its usability. Contrasted with conventional processing machines, for example, the CNC robots , robots are straightforward and use.

Not at all like conventional processing machines, you shouldn’t be a specific robot software engineer to program the robot. With a little preparation assembly line, laborers can figure out how to work the robot and program it for processing.

Improved Accuracy And Precision

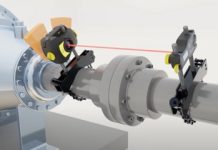

Robots give improved exactness and accuracy in processing activities. A robot gives progressed adjustment in each undertaking it chips away at. This is on the grounds that the robot can undoubtedly reference its situation in the functioning cycle. This guarantees that the eventual outcome is made by the details gave to the robot.

Furthermore, processing robots have different arms. These arms are connected sequentially. This additionally upgrades the exactness and accuracy of robots as they are underway. You don’t need to continue repositioning the robot arms during the processing cycle. This takes into consideration quicker and exact creation.

Smaller Size

Robots are smaller. This implies that they will take up just a limited quantity of room in your manufacturing plant. This makes it simple to move the robot starting with one piece of the production line then onto the next to deal with the various undertakings it very well may be appointed to.

For a little assembling undertaking, they might think that it’s hard to obtain huge manufacturing plant space to run their tasks. With a robot, you won’t need a committed space for a processing machine. This guarantees that it is not difficult to utilize the accessible space ideally.

Utilizations Of Milling Robots In Industry

Material Removal

Quite possibly the most widely recognized application for CNC robots processing robots in the business is material evacuation. Processing robots are utilized for errands like crushing, processing, deburring, boring steering, and other material evacuation undertakings.

Processing robots have inbuilt sensors to detect and convey the right strain to each device and material that they are chipping away at. To the industrial facility, this lessens squander and further develops the creative interaction and limit.

With the right finish of arm tooling for your processing robot, you can undoubtedly do material evacuation jobs in an assortment of materials. You can deal with steel, wood, aluminum, froth, earth, and fiberglass.

This permits an assortment of businesses to purchase processing robots for improved creation and different advantages.

Wrapping up

For a uniform completion of your items, you can utilize processing robots in your industrial facility. They can be utilized for the ideal cleaning task on the entirety of your items.

Utilizing a robot for this undertaking guarantees consistency in your items. Robots likewise complete the errand quicker than human specialists or different machines. This implies that you can complete more items throughout a given timeframe.

Different enterprises, for example, car, aviation, and CNC robots even furniture-production organizations are utilizing processing robots to complete their items as consummately as could be expected.

End

Processing robots are developing more mainstream in the assembling business. An ever-increasing number of makers are seeing the advantages they can acquire with the utilization of robots in their creation cycle. They can be effectively applied for use in assorted areas of assembling. Subsequently, any assembling association can secure a processing robot. With the capacity to likewise deal with different assignments, the robot turns into a fundamental apparatus to the producer.