Pieces of machinery, that’s what the industries these days work on. Not only businesses, but our daily life activities also depend on these few devices. What happens when some of our appliances stop working? That’s where the actual challenge comes into the picture.

Let’s get to the root of these machines. What do they work on?

The Working of A Machine

Machines are equipment designed to convert electrical energy to mechanical energy. This simple yet elucidative description explains the objective of all devices as a whole. Various parts of it are interconnected to provide a specific motion.

Work, in mechanical terms, is referred to as the displacement conjoined with force. It goes with the formula W=Force × Displacement. However, it emphasizes the exertion of force to get a specific task done.

Motor And Its Role In Machinery

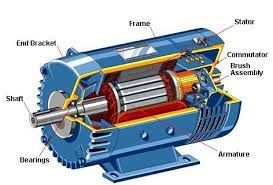

Motors are mechanical devices that convert energy into motion. These are what the machines work on. Any form of energy is first converted to rotational motion. The work on the principle of electromagnetism. A series force is exerted when an electric current is present in a magnetic field. This creates torque, a rotational equivalent of linear force.

Types of Motors

There are many types of motors, some of the basic ones are:

- DC or Direct Current Motors:

They take electrical power through direct currents. It uses a set of stationary magnets around a coil, with current running through it.

- AC or Alternate Current Motors:

They take electrical power through alternating currents. It relies on an alternating flow of current and this kind of motor is widely used around the world.

- Hydraulic Motors:

Hydraulic motors are mechanical actuators that convert hydraulic pressure into torque and angular displacement.

Let’s brush up on the attributes of these motors.

Attributes of Motors

Electric motors are designed in a structured way to attain simplicity as well as efficiency.

They are:

- Cost Effective:

In industries and similar fields, enormous pieces of machinery are used. Every single one of them requires many motors connected. Hence, motors need to be cost-effective and surprisingly, it is.

- Reliability:

With minimal maintenance, it has a high-reliability scope. It has an exceptionally great operational lifespan.

- Efficiency:

These are highly efficient and unlike engines that run on fuels, electric motors don’t need servicing and operate even in unfavorable temperatures, making them ideal for commercial and domestic use.

Motor Malfunction

Appliances can guarantee you perfection in many ways. However, everything is short of absolute perfection and some malfunction is anticipated in everything.

Here are the reasons why motors malfunction, hence making your appliances have a breakdown:

- Contamination:

Our surroundings are filled with dust, and moisture and motors don’t do well with these. These can lead to corrosion and cause its vulnerable parts to stop functioning properly.

- Voltage Imbalance:

In a voltage variation of a power system, if the magnitudes are unequal, this imbalance is created.

- Operational Overload:

When excessive current is drawn with insufficient torque and overheating, operational overload is observed.

- Misalignment:

When the motor drive shaft is not correctly aligned with the load, it results in misalignment.

After discovering these dysfunctions, repair your motor right away.