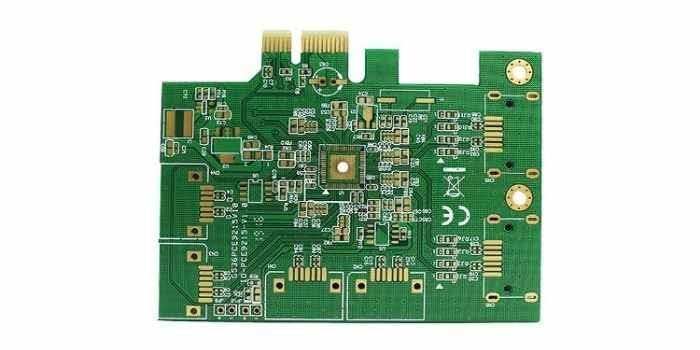

An efficient and versatile multilayer PCB, the 14-layer PCB stack-up may be used for various purposes. It may be tiny, but it packs a significant punch in terms of the advantages it provides, and the variety of fields and applications in which it may be put to use is growing by the day.

When you want eight (eight) signal layers, you will be required to utilize a multilayer printed circuit board device, also referred to as the 14-layer PCB stack up that you will need to employ. In addition, the 14-layer PCB stack-up will be required if you want specialized shields constructed out of nets.

You can tailor the functionality of your 14 layer PCB manufacturing stack so that it meets the criteria specified by various applications. Before a 14-layer PCB stack can be adjusted, the PCB’s thickness and the number of layers must be determined by the maker or producer.

The application areas for a PCB stack of 14 layers are broken below.

Industries

In various industrial applications, the 14-layer PCB stack-up is now a well-known name in the industry. Control systems and industrial computers may benefit from its use. They may also be used in applications related to industry and manufacturing, where they are helpful in the operation of machines. This is possible because of the 14-layer PCB stack’s compact size, functional capabilities, and long-lasting nature.

Electronics

People regularly use several well-known technological devices, including microwaves and smartphones, among other examples. Printed circuit boards are used in every one of these devices; however, rather than the more conventional single-layer PCB, many manufacturers are opting to employ 14-layer PCB stack ups.

Automotives

PCB stack-ups of 14 layers are used in devices such as engine sensors, headlight switches, onboard computers, and GPS systems. In addition, electric vehicles use this stack in various diverse applications.

Medical devices

The 14 layer PCB anufacturing stack is used in a significant number of electronic devices that are used in the healthcare industry. These tools include X-ray machines, CAT scan machines, medical testing equipment, and heart monitors.

Telecommunication

The 14-layer PCB stack-up is utilized in a variety of different general applications, including the devices that are employed in telecommunication. GPS, the transmission of signals, many applications that use satellites, and several more are some. The 14-layer PCB stack is often used for telecommunications applications, typically run on towers outside or on mobile devices.

The Advantages of Using a Stackup With 14 Layers of PCB

The 14 layer PCB manufacturing has various opportunities for improvement in terms of design. These advantages include the following:

Excellent Quality

A lot of labor and preparation must be completed before a 14-layer PCB stack can be created. Because of this, the 14-layer printed circuit board stack seems to have a much higher quality than other types of printed circuit board stack-ups. They also have a higher degree of dependability.

Small size

This PCB stack is more compact than other stacks that provide a capability similar to its own. This is a result of its multi-layered construction. In addition, the 14-layer PCB stack-ups smaller and more compact size provides an advantage in its use in new technologies.

Strengthening one’s strength

The integration of numerous layers into a single printed circuit board is accomplished by the 14-layer PCB stack-up. This is one of the reasons why they provide such impressive speeds.

More durability

With a PCB stack-up with 14 layers, you will have no trouble withstanding the intense pressure and heat and the weight they bring. In this step, you can join the layers using prepreg and other applicable materials. In this particular instance, this stack provides an adequate amount of insulation. The 14-layer PCB stack-ups increased durability may be attributed to these factors.

Flexibility

The creation of the 14-layer PCB stack-up makes use of adaptable building methods. Because of this, your printed circuit board can bend in different directions. You need flexibility for bending and flexing in situations when there is a possibility that just minor bending and flexing may occur semi-regularly.