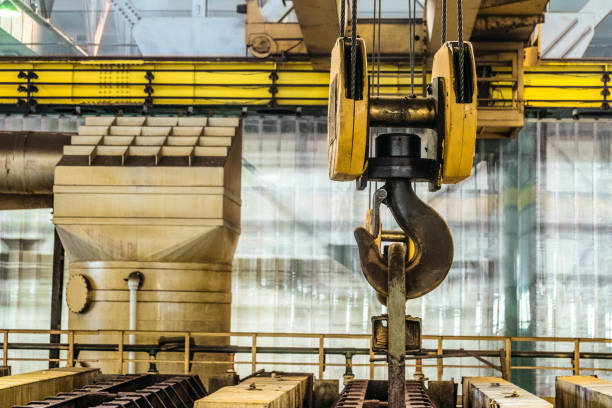

Electric hoists do a great job when it comes to lifting heavy objects. Industries worldwide use these machines to make their work more accessible and efficient. Hoists come in different forms and sizes, and they work differently. However, this article focuses on electric hoists and their benefits. So, read on.

-

What is an Electric Hoist?

An electric hoist is a machine that uses electricity to move heavy loads. They reduce the risk of injury for anyone who must lift a heavy object at their workplace. When places like building sites need cleaning, manual cleaning might be challenging. So, people use this.

Wire rope and chain are two types of it, and they have fast and slow speeds, respectively. People often use the slow-speed type to move the alloy liquid casting or sandbox. Also, a motor powers the wire rope electric hoist’s lifting mechanism; therefore, it completes the lifting action of the wire rope reel.

An electric hoist is mounted on an I-steel track with a certain length and height. Further, the type and size of an I-beam depend on the weight that the electric hoist can lift.

Benefits of Electric Hoists

-

Electric Hoists are Versatile

Generally, hoists are more versatile than human labor. However, electric hoists are more adaptable than other hoists. The reason is that other hoists only lift weights vertically, but they do it both ways. But the type of hoist you use still depends on the kind of project your industry works on and the requirements.

Since the electric hoist can lift weights horizontally and vertically, you won’t need to buy two separate hoists. So, the electric hoist is a significant investment. But if you want to get the most out of this equipment, ensure to get a high-quality one. The only way to do this is to choose a provider with a good track record of reliability to get this lifting gear and equipment.

-

Safe to Use

Every industry takes the safety of its employees seriously. The reason is that the Health and Safety at Work Act of 1974 stated that employees must be safe in the hands of their employers. It have made it easy for workers to escape specific hazards.

However, industries must consider several elements to follow this legislation. These include the quality of equipment and any risks associated with it. Electric hoists consist of safe and high-quality materials. So, it is safe to use in industries.

They are even safer to operate than manual hoists or other manual lifting methods. Manual methods come with several dangers, including fatigue and stress injuries. These injuries can have a long-term impact on people’s lives and professions. So, it’s critical to avoid them as much as possible.

Further, the procedure of using it requires very little human labor. The operator has to turn on the hoist and move it around with basic controls, which requires no real effort.

-

They are Cheap

People often think that less expensive stuff is less effective. But this is not the case with electric hoists. Other lifting equipment is much more costly than electric chain hoists. Electric hoists help industries save a lot of money and invest in other things. Despite their low price, they have a heavier load capacity, making load-lifting faster. As a result, operational running times and the costs that come with them get smaller.

Further, using these machines reduces the employment of too many workers. The reason is that electric hoists don’t need them to do any manual work. So, too many employees may be useless.

-

Less Noisy Operations

Due to its’ internal silencers, they make very little noise. So, they are ideal for a quiet working setting, reducing discomfort and distractions. However, the electric hoist could start making some noise due to faults.

Here are two things to look out for in reducing the noise from electrical hoists are:

- Use multi-pole motor as much as possible. They can lower both motor and gear noise.

- Make high-speed gear teeth more rigid. This reduces elastic deformation and the impact force of gear meshing. The rigidity of gear teeth can be a lot better if the modulus of the gear increases.

-

Electric Hoists are Durable

Electric hoists last long, especially when you get them from trusted suppliers. High-quality electric hoists can work for hours every day and still feel new after many years. They rarely fail, making them long-lasting machines. They are pretty better than manual hoists that break down quickly.

This is especially impressive when compared to manual hoists. Manual hoists tend to break down quickly because of their capacity. But electric hoists don’t have as many moving parts as manual and hydraulic hoists. Therefore, it lasts longer if they are well-maintained and checked regularly.

Conclusion

Electrical hoists have made work more accessible in industries that lift heavy loads. The only downfall of using electric hoists is that they can work automatically, so it doesn’t require too many workers, which can reduce employment. Besides this, it save the employees from several work hazards. Therefore, they have brought better than harm.