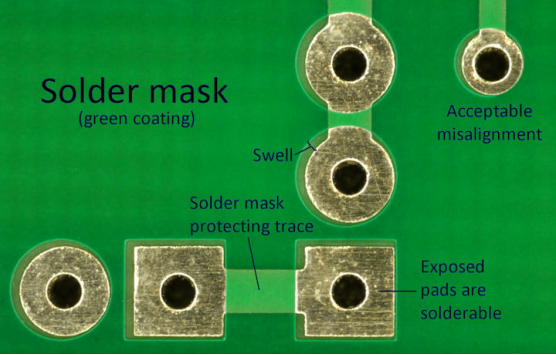

Solder Mask

Introduction: Printed Circuit Boards (PCBs) are the unsung heroes of modern electronic devices, seamlessly connecting components to bring gadgets to life.

Understanding the Solder Mask Layer:

What is a Solder Mask?

The solder mask, also known as solder resist or solder stop mask, is a protective layer applied to the surface of a PCB. This layer serves a dual purpose: to shield the copper traces from environmental factors and prevent unintentional solder bridging during the assembly process.

Environmental Protection:

The soldermask provides a barrier against environmental elements such as dust, moisture, and chemical contaminants. Exposure to these elements can lead to corrosion of the copper traces, compromising the integrity of the circuit. By encapsulating the copper traces, the soldermask enhances the PCB’s durability and longevity. Read more!

Prevention of Solder Bridges:

During the soldering process, it’s crucial to ensure that solder only adheres to designated areas. Without the soldermask, there is a risk of solder bridging—unwanted connections between adjacent copper traces. The soldermask prevents these bridges by covering the areas where solder should not be applied, allowing for precise and controlled soldering.

The Composition of Solder Mask:

Materials Used:

Soldermasks are typically composed of a polymer-based material; such as epoxy or liquid photoimageable (LPI) soldermask. These materials are applied as a liquid and then cured to form a solid protective layer.

PCB Design and Solder Mask Application:

Design Considerations:

During the PCB design phase, designers must consider the placement of the soldermask layer. Careful attention is given to exposing certain areas for soldering while covering others to prevent unintended connections.

Application Process:

The application of the soldermask involves several steps, including printing, exposure, development, and curing. Modern PCB manufacturing processes often use advanced techniques such as inkjet printing or curtain coating for precise and efficient application.

Conclusion:

In conclusion, the soldermask layer plays a pivotal role in ensuring the reliability and functionality of printed circuit boards. Its protective properties shield PCBs from environmental factors, while its role in preventing solder bridges is crucial for maintaining the integrity of electronic circuits.