Building Cables

The construction industry is one of the most critical sectors in any economy. It involves various activities, such as designing and building structures, infrastructures, and other projects that require high levels of precision and quality. As a result, it requires the use of top-quality materials to ensure safety, durability, and cost-effectiveness.

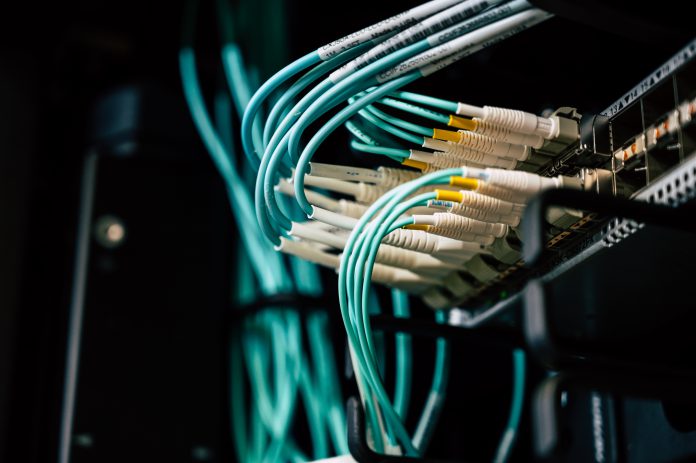

One of the essential materials used in construction projects is building cables. These cables are used for electrical installations, communication systems, lighting fixtures, heating systems, among others. They play a crucial role in ensuring safe and efficient operations on site. Therefore, this article explores different types of building cables available for construction projects and their importance in ensuring smooth project execution.

Understanding The Purpose Of Building Cables In Construction

Building cables are an essential component in construction projects. These specialized cables provide power, data transmission, and control signals to various equipment used on-site. They are designed to withstand the harshest environments and conditions where other types of wires may fail.

The primary purpose of building cables is to ensure safe and reliable transmission of electricity from one point to another. This is achieved through their unique design that incorporates high-quality materials such as copper conductors and insulation layers. Building cables come in different sizes and specifications depending on the type of project they are intended for.

In addition to transmitting electrical current, building cables also play a crucial role in data transmission and signal control. Many modern construction sites use advanced technologies that require sophisticated cabling systems capable of handling large volumes of data while maintaining optimal performance levels. Different types of building cables cater to specific applications, ensuring seamless connectivity across all aspects of a construction project.

Types Of Building Cables For Different Applications

Having understood the purpose of building cable in construction, it is essential to explore the various types available for different applications. The type of cable used depends on factors such as voltage requirements, environmental conditions and safety considerations. Choosing the right type of cable ensures efficient power transmission and reduces maintenance costs.

One common type of building cable is the armored cable, which consists of a conductor surrounded by insulation materials and an outer protective layer. It offers protection against mechanical damage, moisture, and vermin infestation. Another popular option is the flexible cord or portable cord that provides flexibility in installations where movement is required, allowing easy repositioning without damaging the wire.

For high-voltage applications, extra-high-voltage (EHV) cables are ideal due to their ability to transmit large amounts of power over long distances with minimal energy losses. These cables can withstand extreme weather conditions and have excellent insulation properties. Understanding these types of building cable helps builders make informed decisions when selecting appropriate wire for specific projects.

When considering factors to select building cable, several aspects come into play; one important aspect being cost-effectiveness. It’s crucial to balance quality versus price while ensuring compliance with relevant standards such as National Electrical Code (NEC). Other critical factors include installation environment, durability requirements, expected lifespan and compatibility with other systems within the project scope. By taking all these factors into account during selection, builders can be confident about creating safe and reliable electrical installations that meet project specifications.

Factors To Consider When Selecting Building Cables

When selecting building cable, there are several factors that must be taken into consideration. The first factor is the cable’s capacity to carry a load without overheating or breaking down. This capacity can be determined by checking the cable’s ampacity rating, which indicates how much current it can safely handle. It is important to choose a cable with an appropriate ampacity rating for the intended purpose of your construction project.

Another crucial factor in choosing building cable is their insulation material and thickness. Good quality insulation ensures that wires do not come into contact with each other or with other objects, reducing the risk of electrical hazards such as short circuits and electrocution. Insulation also protects wires from damage caused by exposure to moisture, chemicals, and extreme temperatures. Therefore, it is essential to select high-quality insulated cables that meet industry standards.

Lastly, when selecting building cable, one should consider the type of installation environment where the cable will be used. Different environments require different types of cables; for example, underground installations require waterproof cables while overhead installations need UV resistant ones. Choosing the right type of cable for the installation environment helps ensure safety and reliability.

In summary, selecting suitable building cable involves considering several critical factors such as ampacity ratings, insulation materials and thicknesses, and environmental requirements. Making informed decisions about these factors helps increase safety and efficiency in construction projects by ensuring optimal performance of electrical systems.

Importance Of High-Quality Building Cables In Construction Projects

High-quality building cable play a vital role in the construction industry. They are used to transmit electricity and data, making them essential components of any modern infrastructure project. Ensuring that high-quality building cable are installed is critical for ensuring safety, reliability, and efficiency.

One reason why using high-quality building cable is important is because substandard products can lead to electrical hazards such as fire or electrocution. Inferior quality cables may not be able to withstand the demands placed on them during operation, leading to overheating and other problems that can compromise their structural integrity. To avoid these risks, it’s crucial to choose high-quality building cables that meet international standards.

Another benefit of using high-quality building cables is improved performance. Quality cables have better insulation properties, which means they can carry more power with less resistance. This leads to higher energy efficiency and lower operating costs over time. Additionally, high-quality cables are less likely to experience outages or other issues that can disrupt operations or cause downtime.

In summary, choosing high-quality building cables is essential for ensuring safe and efficient construction projects. By selecting reliable products that meet international standards, builders can reduce the risk of accidents while improving overall system performance. In the next section, we will discuss best practices for installing and maintaining building cables to ensure optimal results over time.

Proper Installation And Maintenance Of Building Cables

Installation and maintenance are critical aspects to ensure building cables perform optimally. Improper installation can result in damage, which could lead to fire incidents or electrical shocks. Therefore, it is imperative that qualified professionals handle the installation process. They should follow the manufacturer’s instructions to avoid compromising the cable’s integrity.

Maintenance involves frequent checks on the condition of the cables to identify any signs of wear and tear. The frequency of these checks depends on various factors such as usage intensity, environmental conditions, and type of cable used. For instance, high voltage cables require more regular checking than low voltage ones due to their sensitivity to moisture and temperature variations. Regular maintenance allows for timely detection and correction of defects before they become hazardous.

Proactive measures such as proper installation techniques coupled with scheduled maintenance are essential in ensuring optimum performance from your building cables. These measures help detect potential hazards early enough, thus avoiding costly repairs or replacements down the line. Always consult a professional electrician when installing or maintaining your building cables to guarantee safety and longevity.

Conclusion

In conclusion, building cables are an essential component in construction projects. The selection of the right type of cable is crucial to ensure that it meets the specific application requirements and standards. It is important to consider factors such as durability, flexibility, resistance to environmental conditions and safety when selecting building cables.

Furthermore, high-quality building cables play a significant role in ensuring that construction projects are completed efficiently and effectively. Proper installation and maintenance also contribute towards enhancing the longevity and performance of building cables. Therefore, it is imperative for contractors, engineers and builders alike to invest in quality products like building cables to guarantee successful construction project outcomes. Remember: “You get what you pay for.” Investing in high-quality materials now can save money in the long run by preventing costly repairs or replacements down the line.