Introduction to control cabinets

Control cabinets play an important role in industrial automation as they control complex machinery and processes in many different industrial environments.

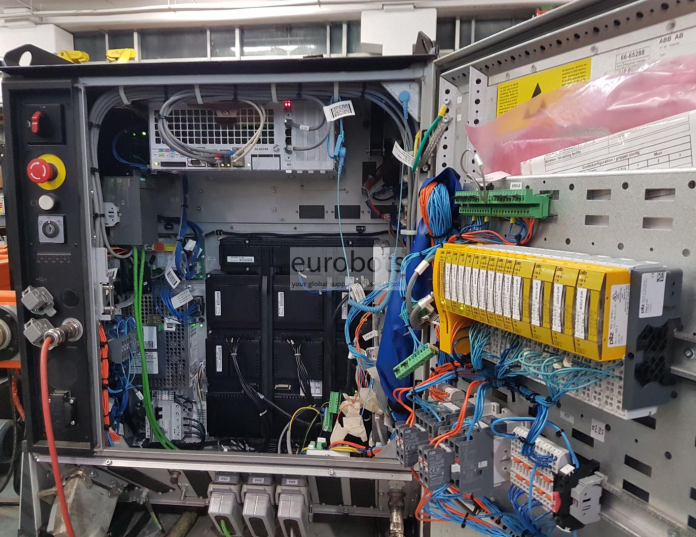

Essentially, a control cabinet is a specialized enclosure designed to protect fragile electronic equipment from ecological factors such as humidity, dust and electromagnetic interference. In these control cabinets, engineers specifically place components such as PLCs, relays, switches, sensors and other important components that form the basic structure of industrial automation. Next, let us explore control cabinets from the four brands of ABB, FANUC, YASKAWA, and KUKA.

Control cabinets from ABB, FANUC, YASKAWA and KUKA

- ABB Control Cabinets

ABB is considered the global controller in power technologies and industrial industries, which is why its control cabinets are also a fundamental part of its comprehensive solutions. Reliability, modularity, and scalability were the main focus during the design of ABB’s control cabinets. These cabinets contain several components including ABB’s variable frequency drivers (VFD), programmable logic controllers (PLC), and other essential automation parts.

- FANUC Control Cabinets

Popularly known for its industrial robotics and CNC systems, FANUC provides control cabinets that are designed for efficiency and accuracy. FANUC cabinets house the different control units for their robotic arms, CNC controllers, and peripheral devices. These cabinets are distinguished by their compact design and modern motion control capabilities. FANUC’s focus on user-friendly interfaces and fast communication inside the cabinets adds to the whole performance and adaptability of its automation solutions.

- YASKAWA Control Cabinets

When it comes to motion control and robotics solutions, YASKAWA is the top supplier. YASKAWA’s control cabinets accommodate servo drivers, motion controllers, and proprietary controllers for robotic systems. YASKAWA’s devotion to energy efficiency is highly evident in its features such as regenerative braking, contributing to the sustainable and cost-efficient automation results.

- KUKA Control Cabinets

KUKA matches strongly with industrial robotics, due to which its control cabinets are engineered to fit in with the precision and diversity of its robotic systems. These cabinets showcase the company’s modernized robot controllers, safety systems, and connectivity results. KUKA’s control cabinets are widely acknowledged for several features like their robustness and the ability to control and maneuver complex programming tasks.

Control cabinet accessories

- Accessories for ABB control cabinets

Power modules and power supply units: ABB provides a wide range of power modules and supply units that are engineered for reliable and efficient power distribution within the control cabinets. These modules provide necessary electrical energy and their power solutions have advanced features like power factor correction which ensures optimal performance and energy savings

I/O modules: These facilitate communication between the control system and different sensors, devices, and actuators on the factory floor. These modules process input signals from sensors, delivering output signals to actuators.

Control panel: These control panels act as a user-friendly interface connecting operators to automation systems. Providing easy access to control functions for efficient monitoring, the panels integrate advanced technologies that include features like robust switches and emergency stop buttons that ensure safe automation system control.

Logic control: PLC is used to execute the logic control functions of industrial robots. It receives signals from sensors, encoders and other input devices and performs corresponding logical operations according to pre-written programs. This includes monitoring inputs, making decisions, and controlling outputs to achieve the robot’s intended function

- Accessories for FANUC control cabinets

Power supply units and power modules: The power supply can also provide auxiliary power for industrial robots to supply the power needs of robot peripherals and accessories.System modules and expansion modules: System modules integrate smoothly with the control system that assist in effective communication and coordination. Furthermore, expansion modules allow the adaptation of the control system to modern automation needs.

Temperature sensors and cooling equipment: FANUC’s temperature sensors and cooling equipment are engineered to regulate the temperature levels inside the cabinet. This prevents overheating and maintains the reliability of the automation system.

Safety modules and protection devices: These accessories are designed to monitor and respond to dangerous conditions, that ensures the safety of the equipment and personnel. They may also include features such as emergency stop functionality and safety interlocks, ensuring a proper layer of protection in industrial environments.

- Accessories for KUKA control cabinets

Control unit and main unit: The control unit contains the intelligence and programming logic, meanwhile the main unit coordinates and completes commands. Both of these combine to form the central nervous system of KUKA’s robotic and automation solutions.

Power management module: It is responsible for effective and reliable power distribution, ensuring that the connected devices receive the electrical power without the compromise of the stability of the system.

Digital imput/output module (DI/DO module): These modules facilitate effective communication between the control system and external devices. Their main focus is processing digital signals and translating commands from the control unit into actions and vice versa. They provide a flexible interface for connecting sensors, actuators, and peripheral devices.

- Accessories for YASKAWA control cabinets

Control module and processor unit: These components act as the heart of the automation system, containing advanced control algorithms and programming logic. The processor unit and control module work together for precise coordination and completion of tasks within the robotic system.

Communication cards and communication interfaces: They ensure effective communication between the control system and peripherals. These communication solutions are designed to support different communication protocols that enable integration with various industrial equipment and systems.

Expansion modules and slots: These accessories provide flexibility for the betterment of the system’s capabilities by adding new features. Their approach also makes sure their robotic system can adapt to the evolving technological advancements.

Cooling fan and temperature sensor: In the maintenance of the reliability of electronic components, temperature management plays a crucial part. The integration of cooling fans and temperature sensors prevents overheating and provides optimal operating conditions.

Conclution:

The industrial robot control cabinet is the core control unit of the robot system. It is responsible for controlling and coordinating the movement of the robot, processing data and algorithms, connecting external devices and systems, and providing power supply and safety protection. Its role is to ensure the efficient, intelligent and safe operation of the robot system.